WA:+8613437301320

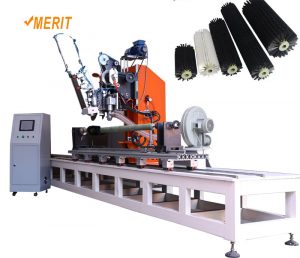

This MTRD1.5M is used to make those big and long industrial roller brushes. With a drilling-head and a tufting-head, it can drill holes and tuft filaments synchronously. It’s installed with automatic vacuum cleaner and manual lubrication system.

2) It’s convince to set up programs. Operator just need enter the holes of roller brush and disc brush :

After you make the program, he just need confirm the position of the first hole on the roller piece, then, the program is finished, which takes only about one or two minutes, is very simple and convenient.

3)whatsmore ,it could make thousands of different roller brush models, on condition that operator changes grippers and sets up programs accordingly.

描述

- This 3 axis one drilling and one tufting machine MTR1.5M,worked with the plant fiber which can be running smoothly . Its designed for the industrial roller brush and disc brush for the road and others industrial used. The length of roller brushes and dia of disc brush are available to make according to customers requirement.

- Details of brushes : The max length of brush block will be 1000MM(customized); The max dia of brush block is 200MM ;The dia of disc brush is 400MM ,the max of it is 500MM .

- with one flexible gripper on the working table ; the max working speed will be 4-7holes/sec

- Customized machine can betufted the machine with abrasive,PP,PET, bristle,abrasive wire others.

- Independent 3 axis motion ,simple, stable

其他信息

| 重量 | 2000 kg |

|---|---|

| 尺寸 | 2500 × 1900 × 2100 cm |

| voltage | 220V or 380V |

| Dia of holes | 5-8holes/sec |

| Dia of fiber | 0.4 -1 mm |

| PLC size | 5.7inch (Chinese &English),50-60HZ |

| Filament outside holes | 30-120mm |

评价

目前还没有评价