WA:+8613437301320

Merit–We are not only passionate about taking care of your after sales service in brush machinebut also supplying the plastic mould , filament, metal broom handle in the most competitive price in order to supporting our customers who doesnt have any idea to start the business in first time to start a project.

Maintain the customer Royalty and the retentation rate is the priority task in our factory . The more clients satisfied with our service ,the more happier we are .The relationship with the clients is closely from the preparation to the machine production, between the customer and Merit, an exclusive and stable collaboration improved by after-sales assistance and supply of original spare parts.

Our sales network is available golbally , Mainly in Turkey,Pakistan ,South Africa ,Mexico ,Brazil,India,Etc .

we are supply the plastic mould ,and the filament, and the broom handle in the competitive price .To make the completed project for our customers who doesnt have any idea to start the business in first time.

Certificaiton of machines :

our machines is available to make the CE certification according to different country requirement.

Years in brush machine business

Quality machines

R&D technical

Opening hours

we are Merit

with high end quality,best service

with

Our Management

we are focus on making the high speed brush machines .

Petsy Love

Fusce at nisi eget dolor rhoncus facilisis mauris.

meet our cleaning family

Passionate About customer after-sales service

India customers Training

Installation & Commissioning: Once the machine arrives, our certified engineer will travel to your site. They will oversee the final installation, connection to utilities, and commissioning, ensuring the machine operates to the same high standard as it did during the PAT.

Russia Customer order

Our commitment to you continues at your facility to ensure your team is confident and your machine is performing optimally.

.

Germany clients training

- Our engineer will provide a refresher course for the operators who attended the initial training and can also train any additional staff. The focus will be on operating the machine in your specific production environment.

- We will then commence live production, running the mop nad brush machine as part of your daily workflow to ensure it integrates smoothly.

What to read

Popular articles about brush and mops

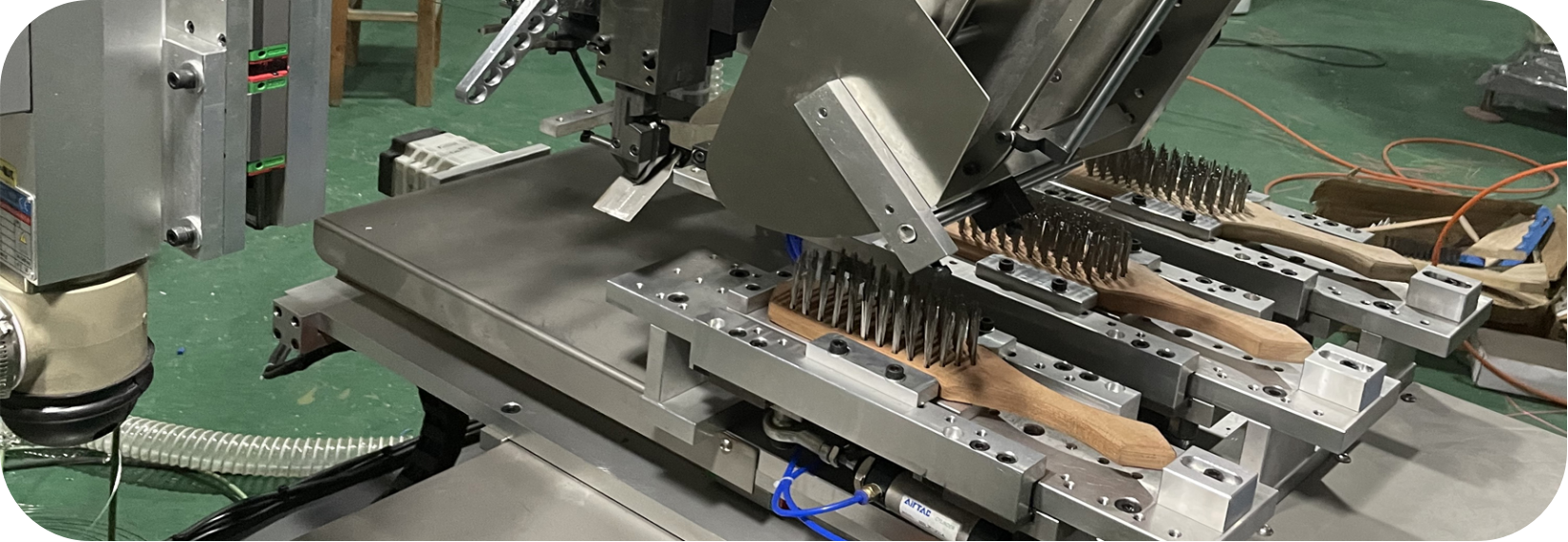

- Feature of our machines:

- Our machines can process different size of Fibers from PP Filament to PET Filament to Nylon Filament to Abrasive Filament and Natural Fiber from Palmyra, Cocoa Fiber, Tampico.

- Options of Filling Tools from sizes 2mm to 7.5mm hole diameter.

- Options of Staple Tufting to Anchor Tufting.

- All machines are CNC Controlled with the latest Software following the Industry 4.0 Automation including Alarm features that allows you to detect the location of the fault on our machine.

- Production speeds from 250 Holes (Tufts) per minute going upto 900 Holes (Tufts) per minute.

- The most important feature of our machines is local service and support in Brazil,China etc .

- Options of Filling Tools from sizes 2mm to 7.5mm hole diameter.

- Options of Staple Tufting to Anchor Tufting.

- All machines are CNC Controlled with the latest Software following the Industry 4.0 Automation including Alarm features that allows you to detect the location of the fault on our machine.

- Production speeds from 250 Holes (Tufts) per minute going upto 1000 Holes (Tufts) per minute.

- The most important feature of our machines is local service and support for our Indian as well as Italian Make Machines,

- Precision and Accuracy of the tufted brush and above all non-stop, continuous productivity.