WA:+8613437301320

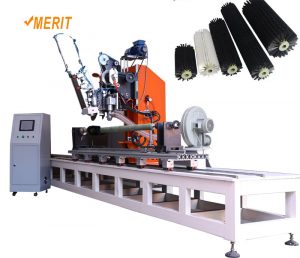

Maintenance of 3-Axis hair brush making machine

1) Operator should often add lubrication oil to the working parts of this toilet brush machine, so as to decrease abrasion.

2) Operator should regularly check each part to see whether there is a loose screw, and please make sure to tighten it, if he finds a loose one.

3) Please keep guide rails and ballscrews clean, and make sure that there is no scrap sticking on them, so as not to decrease the precision.

4) Be sure the machine spare part is moving smoothy , and keep the spare part in stock .

描述

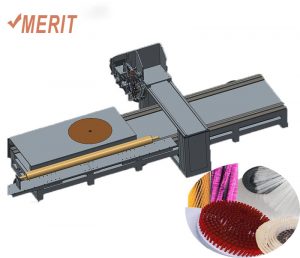

1) 3axis hair brush tufting is a very popular model for making plastic hair brushes with curved surfaces. There are one grippers holding 1 brushes on worktable. Under “Automatic Mode”, it tufts toilet brushes continually, non-stop. Under “Semi-Auto Mode”, it stops after it finishes a brush, and it doesn’t resume working until operator presses “Start”, which is suitable for a new hand.

2) the most important fearture of this machine is the competitive price ,lower investment high return.

其他信息

| axis | 3 |

|---|---|

| production speed | 4-8holes/sec |

| Stations | 1 |

| Tufting Method | flat wire |

| Motors | Panasonic servo motor |

| length of filament range | 30-50 MM |

| Power Supply | 550w |

| voltage | 220V/380V |

| size | 1200*900*1100MM |

| weight | 500kg |

评价

目前还没有评价